Cloud-Based PLM

Your Essential Product Management Tool

FusePLM is an affordable, cloud-based solution for manufacturing companies to efficiently manage parts, BOMs, documents, issues, and changes, accelerating product releases and helping engineering companies bring products to market faster.

Client Location

USProject size

SMEBusiness Model

Mid- Level ProjectClient Background

SMEs, Startup, Manufacturing firms, Engineering firmsThe

Con

Cept

About Project:

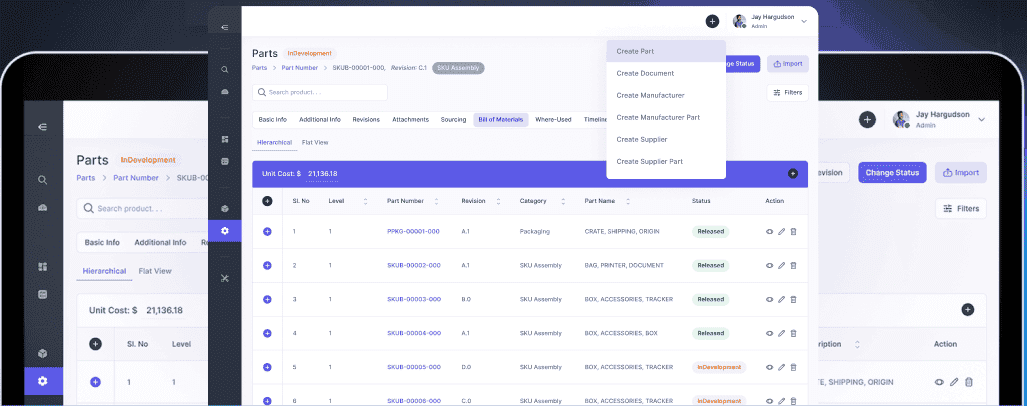

Designed for manufacturing companies, FusePLM is an affordable cloud solution that simplifies the management of parts, BOMs, documents, and change processes, helping engineering teams accelerate product releases and market entry.

About Project:

The FusePLM project aims to enhance product lifecycle management for manufacturing companies with an affordable, cloud-based solution.

Deliver a Cost-Effective and Scalable PLM Solution

Streamline Management of Bills of Materials (BOM)

Enable Customization and Flexibility

Product Lifecycle

Management

PROBLEMS

AND

SOLUTIONS

PROBLEMS

SOLUTIONS

High costs of proprietary PLM systems

Open-source model reduces overall expenses

Lack of Flexibility and Customization

Customizable features allow businesses to tailor the system to their needs.

Difficulty Integrating with Other Tools

Modular design simplifies and streamlines integration with existing tools.

Complex Management of Separate Systems

A unified, cloud-based platform integrates ERP and product management for easier system management.

A unified, cloud-based platform integrates ERP and product management for easier system management.

A single platform consolidates both ERP and product management functions, offering an all-in-one solution.

PROBLEMS

High costs of proprietary PLM systems

Lack of Flexibility and Customization

Difficulty Integrating with Other Tools

Complex Management of Separate Systems

A unified, cloud-based platform integrates ERP and product management for easier system management.

SOLUTIONS

Open-source model reduces overall expenses

Customizable features allow businesses to tailor the system to their needs.

Modular design simplifies and streamlines integration with existing tools.

A unified, cloud-based platform integrates ERP and product management for easier system management.

A single platform consolidates both ERP and product management functions, offering an all-in-one solution.

Approach and Process that you follow

/01

Market Analysis

We have started conducting market analysis to understand user needs and pain points in product lifecycle management, gathering valuable feedback to inform our development process.

1

/02

Roadmap Development

We are defining clear project objectives and developing a comprehensive roadmap that includes milestones and timelines, ensuring alignment with our strategic goals.

2

/03

Modular Design Planning

A focus on creating a modular architecture is underway to enable customization and scalability, allowing seamless integration with existing tools used by our target users.

3

/04

Prototyping and Development

We are in the prototyping phase, designing user interfaces and developing core functionalities like BOM management, while conducting iterative testing to refine features based on user insights.

4

Key

Features

AI Potential Features

AI Features

Demand Forecasting

AI predicts product demand to improve inventory management.

Smart Document Management

AI enhances document retrieval and organization, saving time.

AI-Driven Parts and Suppliers Recommendations

AI recommends optimal parts and suppliers for cost-effective procurement.

AI Potential Features

Challenges and

AND

Solution

Challenges and

Defining reusable report templates for various generation needs.

Managing a complex N-level parts hierarchy structure with real-time updates.

Integrating the ERP system for streamlined task assignments and data collection.

Automating part, product, and document number generation to reduce manual entry.

Ensuring efficient real-time data management across software modules.

Solution

Implemented Dynamic Jasper Reports for flexible, reusable report templates.

Utilized recursive algorithms to maintain the BOM hierarchy effectively.

Developed a card-based workflow with real-time notifications for task assignments.

Automated generation of part, product, and document numbers based on predefined settings.

Designed robust data management capabilities for seamless real-time updates across modules.

Outcomes

System for customers to digitally manage the ERP and PLM cycles for products. Documents were managed by PLM system.

0%

Faster ERP and PLM processes

0%

Reduction in document retrieval time

0%

Fewer manual entry errors

0%

Decrease in manual tasks

0%

Quicker product release